The chainplates are mostly polished after running them on the lathe. The grain in the metal is still apparent but the surface is very smooth. Further polish can be achieved if the client desires a mirrored finish.

The corners have been radiused to reduce the risk of injury if you bump into them, now it's time to drill the holes in the chainplate.

Careful measurements have been taken and the centers of the holes have been transferred to the blank chainplate. The holes were verified by stacking the chainplate under the old template and the marks lined up with the center of the holes, proving that everything is accurate.

Once everything is confirmed perfect, the drilling may begin! There are a few important points to remember when drilling through stainless steel:

- It is very hard

- Heat will kill your drill bit

- You need to keep everything lubricated

- Drill slowly

- Drill with very light pressure

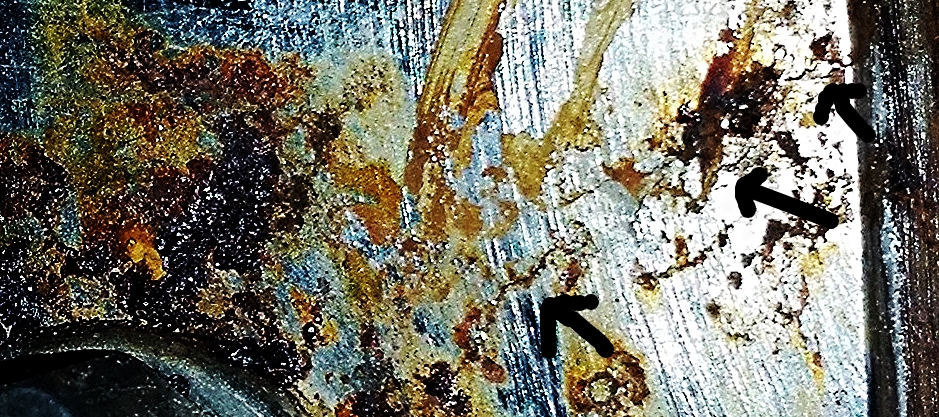

Heat from trying to drill through stainless will cause the drill bit to lose its hardness and dull. To avoid this, you must keep things cool while drilling. To keep it all cool, set the drill press to its slowest speed and keep the drill bit lubricated.

I use transmission oil to lubricate the drill bit because it will begin to smoke if I am pushing it too fast. The oil also keeps the system from creating too much friction (and heat) and helps keep the drill bit sharp for longer. Having a shop vac at the site of drilling also helps keep the metal shavings under control.

As soon as you start to see smoke or the area runs out of oil, stop and add some more transmission fluid to the site.

When drilling the holes, be sure that the old chainplate is securely connected to the new chainplate with at least two C-clamps at all times. Having a third clamp will allow you to re-position the clamps without going below two clamps.

Since the old chainplate is your acoustic guide (if you are slightly off center, the drill bit will scrape the side of the old chianplate and alert you that you need to re-center the unit below the bit) you need the old chainplate to maintain itself in the exact same position. You need at least two clamps to avoid any kind of movement; if the template shifts the slightest bit, the holes will be out of alignment!

At the end of it all, you will have yourself a set of new chainplates with properly oriented holes! The next step in the manufacturing process will be to radius the holes to reduce stresses on the corners of the fastener holes.